Steps To Build - BuildRite LLC Remodeling and Construction

- Home

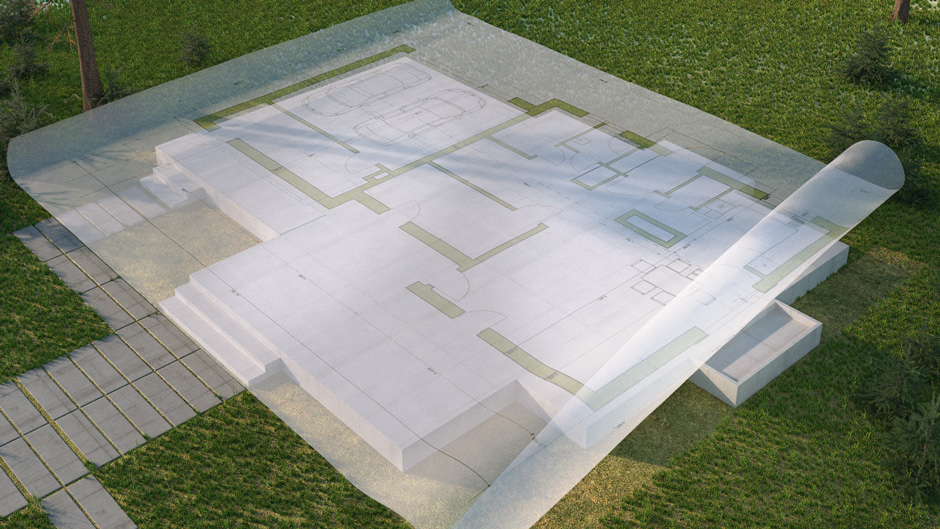

- Steps To Build

1. Obtaining a construction permit To begin building a house, it is necessary to prepare documents such as an urban planning certificate, a building permit containing approvals and agreements from the water and sewer, environment, etc., as well as a geotechnical study based on which the foundation is executed. 2. Realization of the technical project The design of the house is carried out with special, professional programs that check and issue reports on the structure's resistance to wind loads, snow, dynamic loads, loads in the event of natural disasters and deformation in the event of earthquakes. 3. Foundation execution 4. Structure assembly and exterior cladding 5. Placing the roof covering 6. Performing interior and exterior insulation 7. Drawing and installation of electrical and sanitary installations 8. Drawing and installation of electrical and sanitary installations