- buildritellc

- November 17, 2025

- Blog, Blog Standard, General Contractor, Home Renovations

- 0 comment

Installing premium European windows is more than just placing a frame into an opening — it’s a process built on precision, insulation, and long-term performance. In this project, we installed GEALAN high-efficiency windows for a waterfront home, showcasing the same installation techniques used across Europe in energy-efficient construction.

The process begins with proper framing inspection and preparation. Before a single screw is installed, we verify square openings, waterproofing layers, and structural integrity. This step is critical because even the most advanced window can underperform if it isn’t installed perfectly.

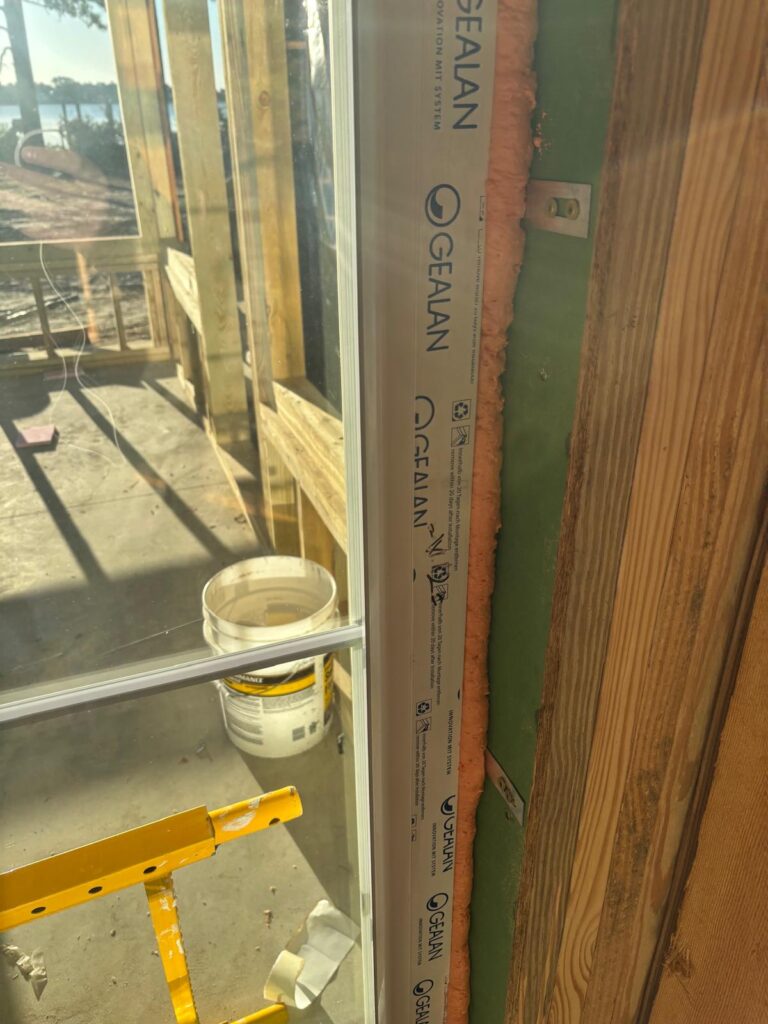

Once the opening is ready, we mount the window using structural steel brackets, a superior method compared to traditional screw-through-frame installations. These brackets keep the frame perfectly level and plumb while also preventing thermal bridging — meaning the window performs better and lasts longer.

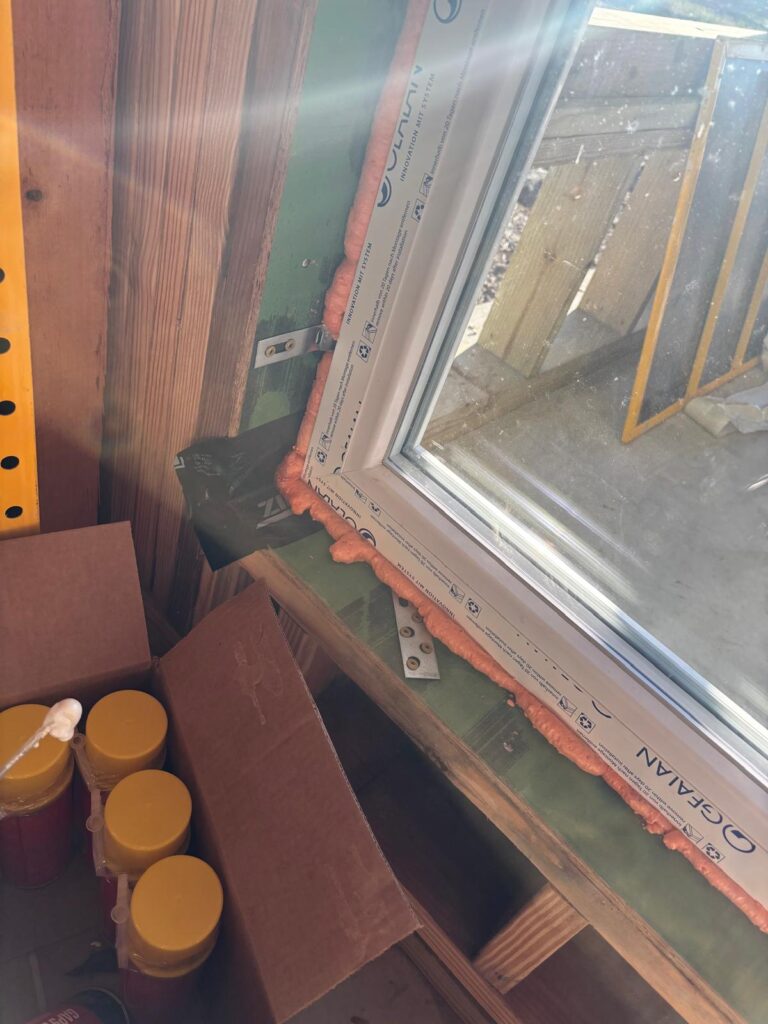

After the frame is secured, we fill the perimeter with closed-cell insulation foam. This foam expands evenly, sealing every gap and improving both energy efficiency and sound reduction. Unlike standard construction foam, the European high-density version provides better temperature control and prevents unwanted air movement around the frame.

The final exterior step is wrapping the window with WindowWrap sealing tape, which locks out wind, water, and moisture. This creates a fully sealed envelope around the window, helping the home maintain consistent indoor temperatures and reducing energy loss.

The end result is a window system built to the same standards found in passive homes across Europe — stable, airtight, quiet, and incredibly energy-efficient. Whether you’re building new or renovating, this method ensures lasting performance and comfort.